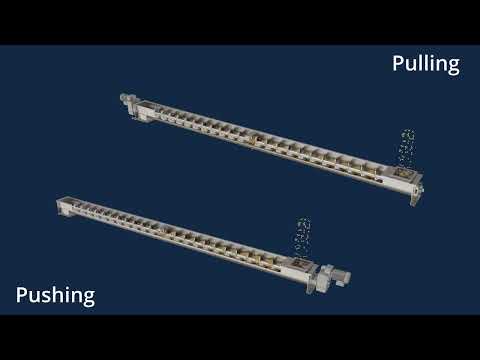

Pushing vs. Pulling Screw Conveyor

The drive unit can be located on either the inlet or discharge end of a screw conveyor. KWS recommends locating the drive unit on the discharge end to pull material towards the discharge. Pulling material toward the discharge puts the screw sections in tension, keeping alignment, which is critical for preventing premature failures.

Video Transcript

What’s the difference between a pulling or pushing screw conveyor drive?

The drive unit can be located on either the inlet or discharge end of a screw conveyor. While drive location does not have an impact on horsepower or speed, KWS recommends locating the drive unit on the discharge end to pull material towards the discharge.

Think of a chain and what happens when you pull or push it. Attempting to push a chain causes it to kink along its length, whereas pulling a chain straightens it out. This concept applies to a screw conveyor assembly, especially one with multiple screw sections. Pulling material toward the discharge puts the screw sections in tension, keeping alignment, which is critical for preventing premature failures.

It is not always possible to mount the drive unit on the discharge end, as some applications may have clearance issues. If you mount the drive on the inlet end and push the material, make sure to add routine checks for potential misalignment to your preventative maintenance schedule.