How to Replace a 226 Style Hanger Bearing

Hanger bearings are a common wear component in a screw conveyor and must be monitored for replacement. If you’re looking to replace a style 226 hanger bearing, watch this video to learn the proper method from the experts at KWS.

Video Transcript

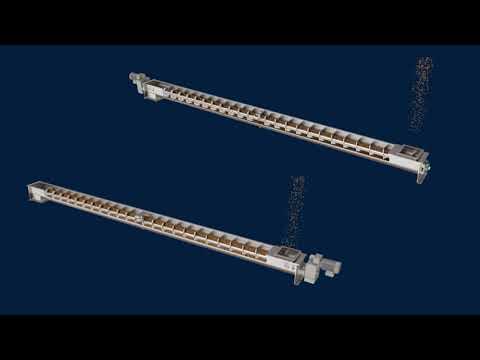

How to Replace a Style 226 Hanger Bearing in a Screw Conveyor

Screw conveyors require routine inspections for component wear or damage. Hanger bearings are a common wear component in a screw conveyor and must be monitored for regular replacement. In most applications, replacing a hanger bearing is easy if you follow these steps.

- Step One – Lock out and tag out power to the screw conveyor to ensure the screw cannot rotate during maintenance.

- Step Two – Remove trough covers located over hangers.

- Step Three – Insert a shim in between bottom of trough and last flights of screws on each side of hanger. The shims can be a small piece of wood to hold screws in place.

- Step Four – Remove countersunk bolts on hanger top bar and bolts on sides of hanger body bars, freeing the bearing. Leave the hanger top bar bolted in place to the trough.

- Step Five – Remove old bearing from coupling shaft and replace with new bearing. Make sure anti-rotation pin is facing up.

- Step Six – Re-install bolts in body bars and tighten around new hanger bearing.

- Step Seven – Re-install countersunk bolts on hanger top bar and tighten to hanger body bars.

- Step Eight – Remove shims between bottom of trough and last flights of screws on each side of hanger.

- Step Nine – Ensure bearing is evenly spaced on each side of coupling shaft, and all hardware is torqued to KWS Operations and Maintenance Manual specifications.

Routine inspections, especially for hanger bearings will extend the life of a screw conveyor and prevent unexpected failures. KWS keeps a wide variety of hanger bearings in stock available for same-day shipment.